Control Panels: A Look Under the Hood

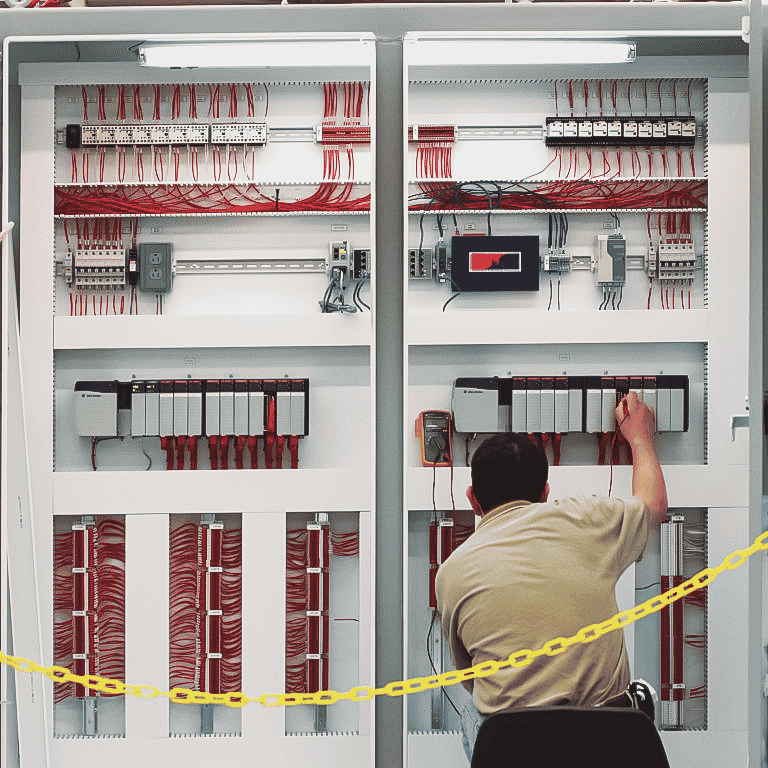

Industrial control panels safeguard electrical, instrumentation, and control components. Industrial control panels are often seen for power distribution, pneumatics housing, and automation electronics protection related to machinery, equipment, and processing systems. They must protect internal components from environmental extremes like temperature, moisture, vibration, and pollutants, all while keeping personnel safe and operations running smoothly.

Control panels, however, are more than just boxes containing various items. They must be carefully developed and manufactured to suit a variety of regulations, norms, and standards, and they must perform their function while remaining usable for decades.

ATRON provides a comprehensive array of enclosures and components and designs control panels for any needs. In this article, we will be diving into everything regarding control panels.

Design Concepts

Proper panel design is typically an iterative and multidisciplinary effort, requiring a skilled engineer to consider the following issues:

- Industry standards

- Job requirements and specifications.

- Protecting components from the environment

- Power and pneumatic distribution.

- Manufacturing & Service needs.

- Safety.

The major North American standards for industrial control panels are UL508A “Standards for Industrial Control Panels,” NFPA 70 “National Electrical Code (NEC),” and NFPA 79 “Electrical Standards for Industrial Machinery.” However, many other standards can be applied to other specific applications and conditions. Additionally, each project and application may have broader end-user or customer requirements.

looking for a Certified, high-speed, quality solution for your manufacturing needs?

Enclosures

The size and configuration of the enclosure must be large enough to accommodate the internal components and fit in the available installation space. However, increasing the size and providing interior working space for future growth is also vital. A big part of choosing the proper enclosure is determining the best mounting method for your application. Floor mounting is standard for large sections, and wall mounting is convenient for smaller designs. Also, wall spacers or floor mounting feet may be required to allow for cleaning in plumbing applications.

Enclosures should be selected to maintain an appropriate NEMA or IP rating for the environment against moisture and dirt ingress. Painted carbon steel housings are standard; although some projects may require a unique paint finish, wet or sanitary applications should generally use stainless steel. For more about metal selection and sheet metal fabrication, please read our article on the sheet metal fabrication process.

An often overlooked detail is that many devices generate heat. Control cabinet design must therefore consider environmental and permissive conditions and possibly provide a suitable cooling system. On the other hand, you may need a heater in cold weather or to raise the internal temperature just enough to prevent condensation in a humid environment that destroys electronics.

Grounding

Proper grounding of conductors, connectors, and terminals ensures reliable and safe operation of electrical equipment. Designers should follow standards for grounding enclosures, internal backplanes, and attached equipment. The primary purpose of grounding is to eliminate power disturbances. That said, good grounding practices are also essential to minimize electrical noise that can adversely affect digital components installed inside the case.

Power Distribution

While some control boards may house only low voltage instruments, it is also common for these control boards to have higher mains voltages and associated components using:

- Front-mounted disconnects

- Circuit breakers and fuses

- Power distribution blocks

- Conductors and cables

- Transformers and power supplies

- Surge suppressors and power conditioners

- Motor starters and variable frequency drives (VFDs)

Controls and Automation

The simplest and smallest control panel can house and protect your device, but most control panels include several automation components, such as:

- Relays

- Buttons and switches

- Programmable logic controllers (PLCs)

- Human-machine interface

- Pneumatic solenoids

- Ethernet devices

Wiring and Connections

Devices and terminal blocks can be screwed directly into the back panel, but many snaps into standard mounting rails. All elements should be placed so that there is sufficient ventilation space to facilitate the connection of conductors and cables using cable ducts. Careful panel design includes accurate identification of devices and cables.

Conclusion

Designing and manufacturing industrial control cabinets requires special knowledge and experience developed over decades. ATRON manufactures safe and reliable control cabinet solutions for any need.