24/7 Support

Our Mission Statement

Protect stakeholder brands while delivering an unmatched, extraordinary experience.

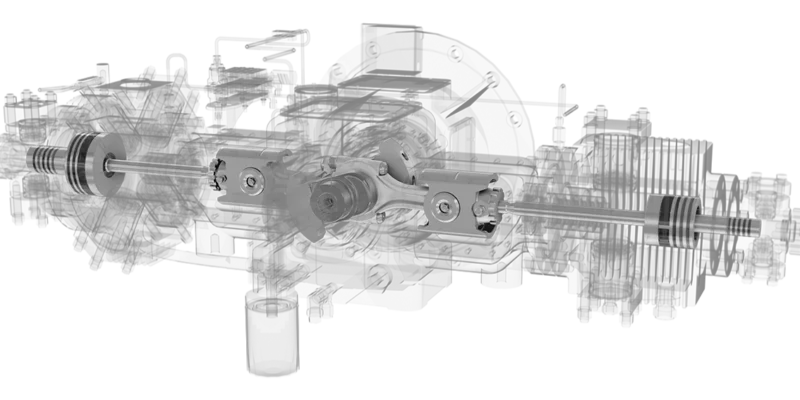

ATRON is a key company in the CNG industry with over 30 years of experience. In conjunction with our partners, we have over 5,000 compressor packages in operation worldwide. ATRON proudly offers a full line of high-pressure compressors and complete refueling stations.

These rugged, multistage compressors are available in many configurations to suit various inlet and discharge pressures and volumes.

ATRON Group follows a world-class method of doing business, growing from ongoing interaction, long-term relationships, and a commitment to understanding each customer’s process and objectives. As a result, every alternative fueling solution we create helps customers operate with greater efficiency, economy, and productivity.

Satisfying customer needs effectively makes ATRON Group the leading alternative energy equipment manufacturer.

Aspro is an international company that manufactures and commercializes compression systems for all types of gases. Its products are used in fuel vending stations, Oil & Gas fields, and in other industrial applications. Since.

Guide to EV charging: from essential...

Delve into ATRON's transformative jo...