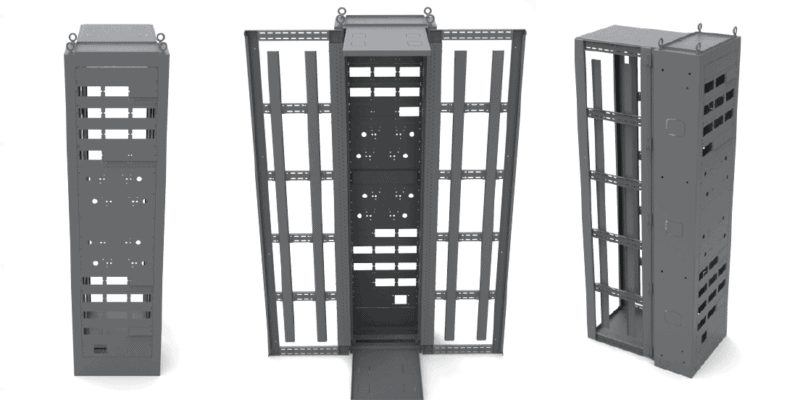

We engineer and manufacture everything in-house which allows us to make custom changes to the design to accommodate most customer requirements. As far as we can tell, this is the only purpose designed and built utility relay rack on the market.

Take a look at our design features below and send us your thoughts.

Feel free to pass a link on to anyone you know in the Utility Industry who may have a need for such a unique product. we think they will thank you (and so will we)!

Z19 Series provides cleaner, faster, smarter wire control. They also protect wires with smooth radius bends.

Swing Out Side Panels

- Up to 90 degrees of side panel pivoting motion

- Fully removable for pre-wiring of components providing full access to the rear terminal blocks and relays; up to three people can simultaneously wire the rack

- Up to 50% reduction in wiring labor hours

- Built-in wire management increases both ease of install and improves overall appearance

- Easy termination of field wiring and maintenance

General Construction

- Swing-out hinged side panels – an innovation that simplifies wiring and maintenance

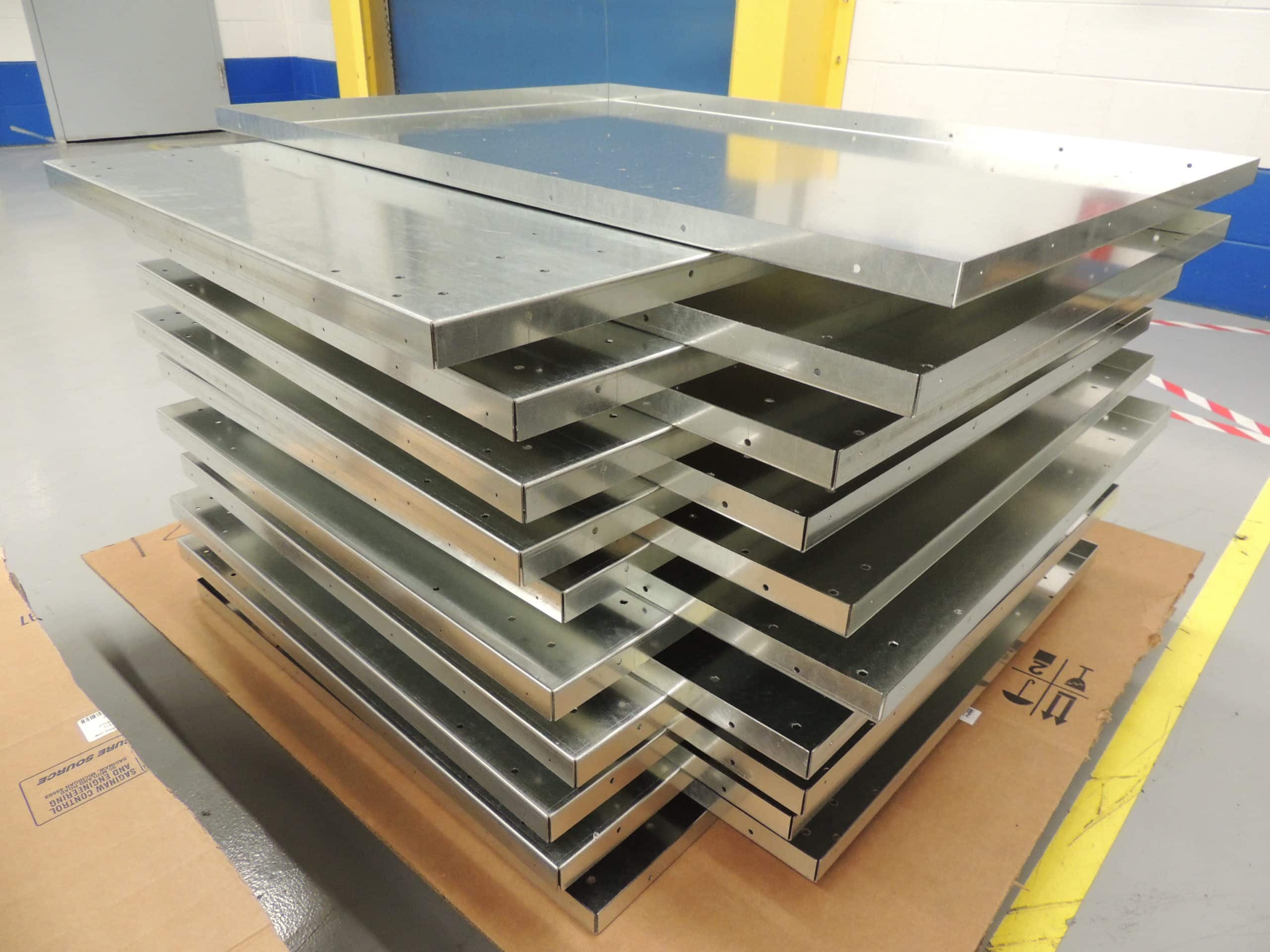

- Precision laser-cut and CNC formed components

- Freestanding frame: Steel (11 gauge standard); optional: aluminum or stainless steel

- Paint colors: ANSI Gray 61 (standard); optional finishes include RAL and custom colors of powder coating

- Substantial structural reinforcement

- Copper ground bus – (continuous length, 2 inches wide x 1/4 inch thick) with four different mounting positions (front, back, top, bottom)

- Pre-punched cable entry knockouts – (4 x 4 inches) located in the top and bottom of the main structure

- Pre-punched side channel cable entry knockouts – (4 x 6 inches) for wiring between racks

- Tray cable entry – integrated 4-inch wire channel between sections for top and bottom feed

- Mounting rails – adjustable and customizable vertical rails for the mounting of terminal blocks and shorting blocks; quantity of 4

- Top lifting eyes (4)

- Device mounting plates (laser-cut)

Wire Management

- Designed to be easily wired, in the plant or in the field

- Integrated (yet removable) and customizable

- Well organized wire routing equals cleaner and faster wiring

- Utilize push-in nylon wire mounts that provides permanent long-life wire support, unlike self-adhesive wire mounts

- Pre-punched holes at 2-inch increments to accept nylon mounts throughout the wire management system

- No sharp edges; nice radius bend that protects the wire from chaffing

- Incoming tray cable wire lashing rails utilize push-in nylon wire mounts

Rack Mount Rails

- Removable and replaceable (not welded)

- Adjustability along horizontal axis provides flexibility depending on devices and clearances required

- Easy to replace if damaged in the field

- Custom rails – available for special applications

- Many combinations available: pre-punched, captive nut, pre-drilled and tapped, or custom hole pattern

- Integrated vertical wire management with push-in wire mounts