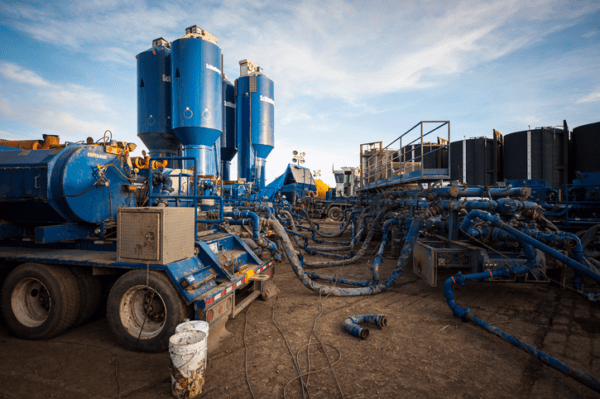

The Next Evolution: Fracking Trucks

The energy industry has evolved and officially rebounded. How would we know? We have walked the front lines of energy trade-shows and they are buzzing! Plus, pay attention to the raw components, specifically sand. The price of sand is surging as oil production rebounds.

Latest Threat to U.S. Oil Drillers: The Rocketing Price of Sand

The process of extracting oil and gas is labor-intensive, highly regulated, and multi-dimensional. Oil and gas impacts every industry and life within the United States. Unfortunately, there is a huge misconception with fracking. The technology and techniques have evolved, but at the end of the day, fracking= drilling.

The article below breaks down the process of drilling, specifically fracking.

Fracking 101: Breaking down the most important part of today’s oil, gas drilling

1. Storage Tank: Holds blend of water and chemical agents.

2. Dump Truck: Delivers sand to the blender truck.

3. Blender Truck: Mixes the blend of sand, water and chemical agents and sends it to the truck.

4. Pumper Truck: Hydraulic pumps shoot high-pressure fluid down into well.

5. Well (Cutaway): Down to about 3,000 feet, the well is reinforced with various cement casings for stability. The interior piping allows for the water and chemical solution to be sent down and back up, along with natural gas. The well drills downward around 8,000 feet, then turns horizontal within layers of shale, which contain natural gas deposits. 6) Natural gas: Gas is pumped out of the well and transported by truck or pipeline to market.

6. Storage Tank: Recovered water is stored then taken to treatment plant or reused.

Chicago Tribune (2014). How Fracking Works. Retrieved from http://www.chicagotribune.com/business/chi-how-fracking-works-html-story-htmlstory.html

The main machinery for fracking – TRUCKS, TRUCKS, and TRUCKS! Multiple trucks are required with specific purposes to carry water, sand, and chemicals. The combined horsepower is required to mix all the elements and shoot down through an eight inch hole to crack open that black gold!

These trucks have many electrical components, specifically molded cables and control panels. Whether you need the electrical components (cables assemblies, wire harnesses and/or control panels) or sheer manpower to help assemble (in-house or outsource), we can assist. Plus, due to future transitioning from manual to unmanned trucks this will soon increase the demand for specialized electrical configurations. A specialist will be required to assist with the electrical standards who align with IPC-WHMA-A-620. You are partnering with an expert who’s protecting stakeholders brands while delivering an unmatched, extraordinary experience.

AssembleTronics is on the front-lines of the energy industry and ready to assist with one of the greatest rebounds in American history. As the saying goes, “The Road Goes On and the Oil Never Ends.”